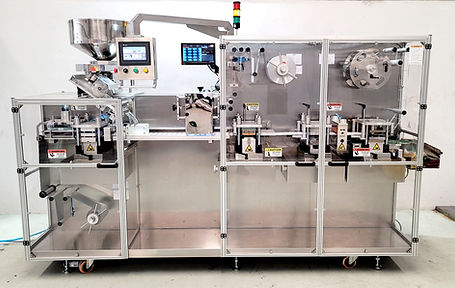

💊 STD. Blister Packing Machine – Mid- to Large-Scale Pharmaceutical & Supplement Applications

For SMEs to Large Enterprises Seeking Cost-Efficient, Stable, 24/7 Production

The STD. Series is a high-performance blister packing machine designed to meet the rigorous demands of industries such as pharmaceuticals, food supplements, cosmetics, and general consumer products. It is especially suitable for production environments that require uninterrupted 24/7 operation with reliability and efficiency.

⚙️ Available Models

-

YCH-220x130-SF

-

YCH-290x150-SF

-

YCH-320x170-SF-V16 (Customized Configuration)

🛠️ Key Machine Features

-

Supports multiple blister types: Alu/PVC, Alu/Alu, Alu/PVDC, Paper/PVC

-

Maximum forming depth: 15 mm

-

High-precision Servo-driven Gripper Chain film transport system

-

Localized thermoforming for consistent forming thickness

-

Flat machine structure allows access from both front and rear sides

-

All product-contact parts made from SUS 316 pharmaceutical-grade stainless steel

-

Equipped with comprehensive safety sensors on all access doors

💻 European-Standard HMI and Control Software

-

10-inch touchscreen: user-friendly, multilingual interface

-

Controlled via OMRON or DELTA PLC with 3-level password protection

-

Complies with 21 CFR Part 11 (electronic records & signatures)

-

Stores up to 50 product recipes

-

Optional Data Logger for exportable operating data, including:

-

Sealing temperature

-

Machine speed

-

Runtime statistics

-

Operator login history

-

Alarm event logs

-

🧰 GMP & EU Compliance-Ready Design

-

Fully adjustable stations (Forming, Sealing, Cutting) for precision changeovers

-

Automatic PVC film lock when the machine is paused for extended periods

-

Cooling system for sealing station during idle time

-

Upgrade options available:

-

Camera vision system for blister inspection

-

TIJ printing system for real-time batch coding

-

✅ Ideal For

-

OEM manufacturers producing various SKUs

-

Pharma and supplement plants requiring strict GMP compliance

-

Facilities with frequent format changes and demanding consistency

BLISTER PACKING FLAT TYPE V16

🧱 1. Flat Type Blister Machine

A Flat Type Blister Machine features a streamlined, horizontal structure where the forming, sealing, and cutting stations are aligned on a single plane.

Foil feeding and product handling proceed in a straight line from left to right, making it easy to operate, quick to install, and simple to maintain.

Key Advantages:

-

Simple, straightforward mechanical layout

-

Compact size, easy to move and install

-

Ideal for small to medium-sized factories or startup operations

-

More cost-effective than other systems — suitable for OEMs, pharmaceuticals, and supplements

-

Limitations:

-

Mechanical components and product contact zones are in the same area (less ideal for cleanroom applications)

-

Cleaning requires careful access to all corners; risk of dust or powder accumulation

BLISTER PACKING BALCONY TYPE V20

🧼 2. Balcony Type Blister Machine

A Balcony Type Blister Machine is designed to clearly separate the product-contact zone from the mechanical and electrical components.

The front section (open-access) houses processes such as tablet filling and foil sealing, while motors, wiring, and mechanical systems are located at the back or top of the machine.

Key Advantages:

-

Fully compliant with GMP / PIC/S / FDA guidelines

-

Simplifies cleaning validation and line clearance procedures

-

Minimizes risk of contamination from dust or metal particles

-

Ideal for pharmaceutical, nutraceutical, or medical device production in cleanroom classes C–D

-

Limitations:

-

Higher investment cost compared to Flat Type machines

-

Slightly larger physical footprint

-

Requires an experienced team for installation and GMP integration

BLISTER PACKING 220-140 Specification

Feature | STD | PRO | CUSTOM |

|---|---|---|---|

Machine Width (PVC) | 220 mm | 220 mm | 220 mm |

Draw-off Length | 130 mm | 140 mm | Customize |

Forming Depth | 15 mm | 15 mm | Customize |

Effective Speed (PVC+ALU) | 25-35 cpm | 25-40 cpm | Customize |

Effective Speed (ALU+ALU) | 25-30 cpm | 25-35 cpm | Customize |

Sealing System | Heat + Temp. Rank Control | Heat + Temp. Rank Control + Temp log. | Customize |

Perforation | Optional | Include | Customize |

Draw-off System | Servo Motor | Servo Motor | Customize |

Cutter | SKD-11 58-60HRc | SKD-11 58-60HRc | Customize |

Material Compatibility | PVC/ALU/PVDC | PVC/ALU/PVDC/PS/PE | User-defined |

Frame & Cover | Steel + Profile + Composite | Steel + Profile + SUS304 Cover + SUS316 Contact | Customize |

Cooling | Chiller Optional | Built-in Cooling | Customize |

Auto Feeder | Optional | Include | Flexible Design |

TIJ System | Option | 10 Head Include | Customize |

Vision System / Eye-mark | Optional | Include | Yes / Advanced AI |

Control System | Standard PLC + HMI | Advanced HMI + Servo | Optional Brand (Omron/Siemens) |

PLC | DELTA | OMRON | Optional Brand (Omron/Siemens) |

HMI | DELTA 10" | DELTA 15" | Optional Brand (Omron/Siemens) |

21 CFR Part 11 | None | Include | Customize |

Audit Trail | None | Include | Customize |

User Access | 2 Level | 3 Level | Customize |

Recipe Management | 10 | 50 | Customize |

Data Backup | None | Include | Customize |

Communication Protocol | None | Modbus TCP, Ethernet/IP | Customize |

Preventive Plan | Option | Screen Alarm | Customize |

Seal force Monitor | None | Option | Customize |

Output Format | Conveyor | Conveyor + Sort | Auto Tray Loader |

PVC Roll End Detection | Include | Include | Customize |

Alu Foil Roll End Detection | Include | Include | Customize |

Air pressure | Digital Rank control | Digital Rank control | Customize |

Cooling Temp Control | Digital Rank control | Digital Rank control | Customize |

Safety Sensor | Include | Include+Log | Customize |

Changeover Parts ID | Manual Check | RFID Check Option | UID/IoT Ready |

After-sale Service | Fast Response | Within 24Hr | Full Validation Support |

IQ/OQ Available | Asian Standard | Euro standard | Deep content |

Dimension | 850 x 4200 x 1850 | 850 x 4300 x 1850 | Customize |

Weight | 950-1250Kg | 950-1350Kg | Customize |

BLISTER PACKING 290-170 Specification

FEATURE | STD | PRO | CUSTOM |

|---|---|---|---|

Cooling Temp Control | Digital Rank control | Digital Rank control | Customize |

Auto Feeder | Optional | Include | Flexible Design |

Cooling | Chiller Optional | Built-in Cooling | Customize |

PVC Roll End Detection | Include | Include | Customize |

Forming Depth | 15 mm | 15 mm | Customize |

Preventive Plan | Option | Screen Alarm | Customize |

Effective Speed (ALU+ALU) | 25-35 cpm | 25-40 cpm | Customize |

IQ/OQ Available | Asian Standard | Euro standard | Deep content |

Safety Sensor | Include | Include+Log | Customize |

Dimension | 750 x 3000 x 1850 | 750 x 3000 x 1850 | Customize |

Material Compatibility | PVC/ALU/PVDC | PVC/ALU/PVDC/PS/PE | User-defined |

21 CFR Part 11 | None | Include | Customize |

Output Format | Conveyor | Conveyor + Sort | Auto Tray Loader |

User Access | 2 Level | 3 Level | Customize |

TIJ System | Option | 16 Head Include | Customize |

Cutter | SKD-11 58-60HRc | SKD-11 58-60HRc | Customize |

After-sale Service | Fast Response | Within 24Hr | Full Validation Support |

Sealing System | Heat + Temp. Rank Control | Heat + Temp. Rank Control + Temp log. | Customize |

HMI | DELTA 10" DELTA 15" | Optional Brand (Omron/Siemens) | |

Recipe Management | 10 | 50 | Customize |

Effective Speed (PVC+ALU) | 15-30 cpm | 25-40 cpm | Customize |

Air pressure | Digital Rank control | Digital Rank control | Customize |

Seal force Monitor | None | Option | Customize |

Vision System / Eye-mark | Optional | Include | Yes / Advanced AI |

Draw-off System | Servo Motor | Servo Motor | Customize |

Frame & Cover | Steel + Profile + Composite | Steel + Profile + SUS304 Cover + SUS316 Contact | Customize |

Data Backup | None | Include | Customize |

PLC | DELTA | OMRON | Optional Brand (Omron/Siemens) |

Machine Width (PVC) | 290 mm | 290 mm | 290 mm |

Control System | Standard PLC + HMI | Advanced HMI + Servo | Optional Brand (Omron/Siemens) |

Communication Protocol | None | Modbus TCP, Ethernet/IP | Customize |

Alu Foil Roll End Detection | Include | Include | Customize |

Draw-off Length | 170 mm | 170 mm | 170 mm |

Changeover Parts ID | Manual Check | RFID Check Option | UID/IoT Ready |

Audit Trail | None | Include | Customize |

Perforation | Optional | Include | Customize |

Weight | 1300-1550Kg | 1350-1650Kg | Customize |